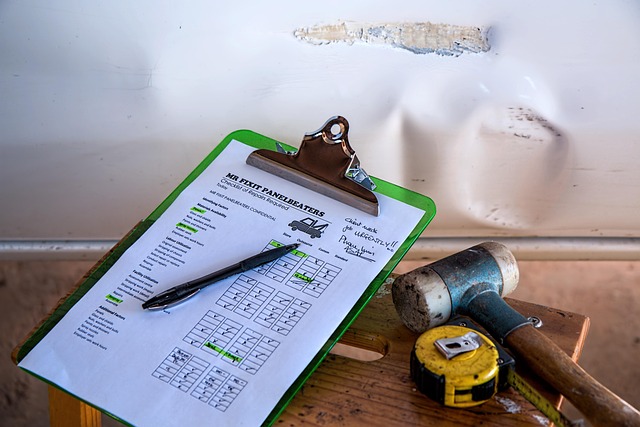

Auto body restoration success depends on material quality and cost, with genuine OEM parts offering precision but high prices, while aftermarket or recycled parts are more affordable. Essential factors for budgeting include initial purchase prices, availability, lead times, labor rates, environmental regulations, and market fluctuations. The process utilizes diverse materials like metals, plastics, and composites, each with unique properties and applications. Cost variations stem from material quality, such as precision-cut sheet metal, painting options (from basic to luxury), and adhesive/sealer strength and resistance. Professionals must consider these factors for accurate quotes, ensuring customers understand costs for achieving flawless finishes in auto body restoration.

In the realm of auto body restoration, a complex dance of artistry and precision, cost is a pivotal consideration. Every component—from raw materials to skilled labor—carries a price tag that contributes to the final bill. Understanding these costs is crucial for both consumers and professionals in the industry. This article delves into the intricate web of expenses involved in auto body restoration, exploring material costs, labor charges, and overhead expenses to equip readers with valuable insights for informed decision-making.

- Material Costs: The Building Blocks of Restoration

- – Overview of raw materials used in auto body restoration

- – Variety of materials and their price ranges (e.g., sheet metal, paint, adhesives)

Material Costs: The Building Blocks of Restoration

The foundation of any successful auto body restoration project lies in the material costs involved. These building blocks are essential to achieving a precise and visually appealing finish. The selection of materials plays a significant role, as different components may have varying price points and quality levels. For instance, opting for genuine OEM (Original Equipment Manufacturer) parts might be pricier but ensures an exact match with the vehicle’s original specifications. On the other hand, aftermarket or recycled parts can offer more affordability without compromising on safety and durability, making them a popular choice among collision repair centers.

Understanding material costs is crucial for both auto body restoration enthusiasts and collision repair professionals. It involves considering not just the initial purchase price of materials but also their availability, lead times, and potential long-term savings. Additionally, factors like labor rates, environmental regulations, and market fluctuations can indirectly impact the overall cost of auto body restoration projects, influencing the final pricing for both customers and businesses in the automotive repair industry.

– Overview of raw materials used in auto body restoration

The process of auto body restoration involves a complex interplay of various raw materials to bring damaged vehicles back to their original condition. Among the most common are metals, such as steel and aluminium, which form the structural backbone of the vehicle. These are often in the form of panels, sheets, and components that make up the car’s exterior. In addition to these, plastics and composites have become increasingly prevalent due to their lightweight properties and versatility. From body panels like fenders and doors to intricate interior parts, these materials require precise handling during the restoration process.

While auto dent repair is a significant aspect of auto body restoration, it’s just one piece of the puzzle. Auto repair shops and car body shops use specialized tools and techniques to shape, reshape, and refinish these raw materials. The choice of materials and subsequent processes directly impact the final outcome, affecting factors like structural integrity, aesthetics, and durability. Thus, understanding the raw materials and their applications is crucial for anyone delving into auto body restoration, ensuring a successful transformation of damaged vehicles into pristine ones.

– Variety of materials and their price ranges (e.g., sheet metal, paint, adhesives)

The cost of auto body restoration can vary greatly depending on several factors, and one of the key aspects is the selection and price of materials. Auto body restoration involves a range of components, from sheet metal and paint to adhesives and sealing agents. These materials can differ in quality, brand, and type, each carrying its own price point. For example, high-quality, precision-cut sheet metal for panel replacements might cost significantly more than standard options, impacting the overall budget for restoration work.

When it comes to painting, choices extend from basic industrial coatings to specialized, durable finishes used in luxury vehicle repairs, such as Mercedes Benz repair shops. Similarly, adhesives and sealers vary in price based on their strength, longevity, and resistance to environmental factors. Vehicle body repair professionals must consider these variations to provide accurate quotes for auto body restoration projects, ensuring customers understand the material costs involved in achieving a flawless finish, whether it’s for regular repairs or specialized tasks like auto body painting.

In the realm of auto body restoration, understanding cost factors is paramount for successful and sustainable projects. From raw materials like sheet metal, paint, and adhesives to labor costs and overhead expenses, each element plays a crucial role in determining the final price. By considering these factors and staying informed about market trends, restorers can offer competitive pricing while maintaining high-quality standards. This meticulous approach ensures that auto body restoration work not only meets but exceeds customer expectations, fostering trust and fostering long-lasting relationships within this vibrant industry.